Intercooler for AUDI TT RS

SHIPPING - RETURNS - WARRANTY - CANCELLATION POLICY

*** Market Conditions after 2020 have changed the landscape of automotive parts. Although we try to stock 1000's of items in our multiple warehouse and use multiple distribution channels, having back-orders are unavoidable in today's market. If you are in need of a product quickly, we suggest email, message, or call us for availability so that we may explore your options.

Email: Sales@Speedzoneweb.com

Call: 407-846-8430

Text: 407-749-6314

Frequently Asked Questions

- 37°C reduction in IATs

- Gains of up to 25BHP

- Overall surface area increased by 30%

- Volumetric capacity of 15.7l

- 130% increase in capacity over the OEM

- One of the largest intercoolers on the market today

- Bar and plate core design

- Lifetime Warranty Guarantee

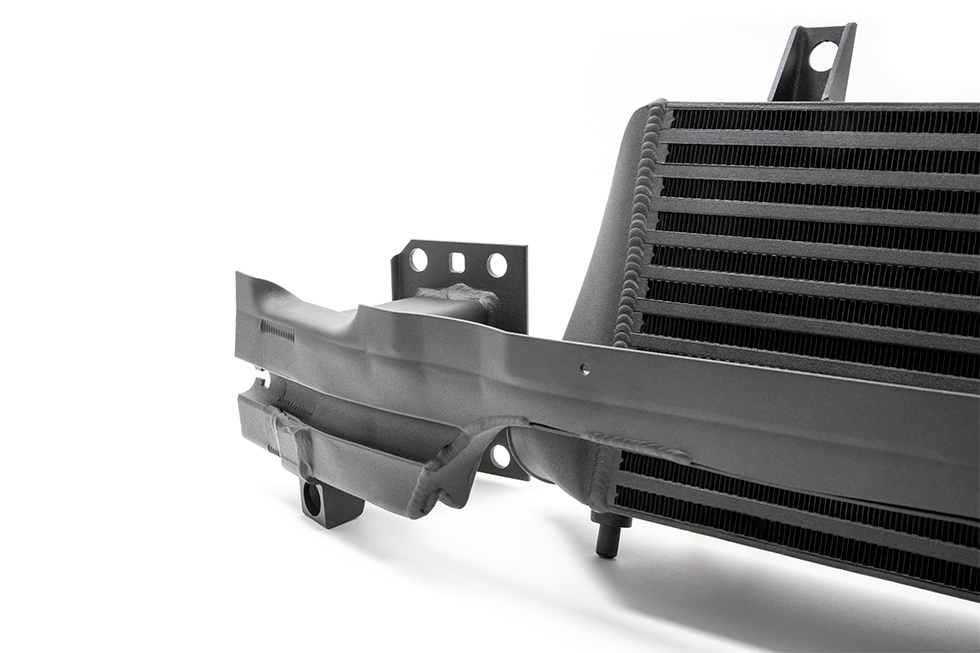

After developing an uprated intercooler for the Audi TTRS 8J, our tuning partners approached us to develop a 2nd version that would be specifically designed for those running 500+ BHP. Even for customers with just a stage 1 tune, gains of around 25 BHP can be expected by just swapping out the relatively small and inefficient OEM intercooler (OE Part No. 8J0145804B).

The standard intercooler fitted by Audi has a volumetric capacity of 6.8l, which essentially bottle-necks the inlet tract to the throttle body, creating a restriction when the boost is increased. We utilised our CAD design to ensure that the end tanks flow in the best way possible, spreading the compressed air evenly throughout, this in-turn lead to superior performance over the stock item. We tested several core configurations during development, with the best all-rounder being our bar and plate design. The overall surface area of the intercooler has increased by 30% providing more cooling capabilities. We utilised all the available space with a volumetric capacity of 15.7l, resulting in an overall 130% increase in capacity over the OEM, making this intercooler one of the largest on the market today.

This intercooler is complimented with our modified OEM crash bar (OE Part No. 8J0807109B), that also doubles as the intercooler support.

Why do we test different cores?

When developing an intercooler, we will test several different cores for each application. For example, a bar and plate style core, and a tube and fin style core. Our tube and fin will be tested with different fin pitches and heights, e.g., 22 fins per inch or 17 fins per inch. We will also look at changing the internal fin pitches/shapes and density within the tube, enabling to fine tune the amount of pressure drop the intercooler produces.

Pressure drop is not always a bad thing, as our testing and research has proven on various projects. This is because the pressurized air velocity is being stalled by the pressure drop within the cooler, thus allowing more time to cool the air within the cooler itself, as air passes through the non-pressurized face of the core that is open to the atmosphere. Too much pressure drop can of course have a problem on the higher performance engines. As the intercooler reaches its maximum efficiency, the turbo must work a lot harder to force the air through the core. This in-turn creates higher inlet air temps (IAT’s) due to the turbo creating more heat as it is being worked harder.

Having no pressure drop can also prove to be inefficient, as the cooler will not lower the charge temperature again, resulting in higher inlet air temperatures.

Dyno Results

Testing was completed using an independent dyno, we used Powerstation in Tewksbury on their MAHA dyno. This was manufactured by the same people who currently supply BMW M Sport and Mercedes Benz for all their engine calibration and dyno testing.

During testing, we let the car heat soak on the dyno until the radiator fans tripped on and off (which gives an inlet temperature of 38°C), then did a dyno pull from there. This gives a more consistent result and reflects real-world driving conditions more accurately. You can easily see the Forge Motorsport intercooler cools much quicker and delivers a greater drop in temperature compared to OEM.

The OEM intercooler produced inlet air temperatures on average of 72°C after 3 pulls, while the Forge Motorsport intercooler reduced the inlet air temperature to 35°C, resulting in a 37°C reduction over the stock item, and being far more superior than our first iteration that has since been discontinued.

The dyno graph shows the comparison between a highly tuned TTRS running our original revision Forge Motorsport intercooler, and after installing the 500+ BHP version. The results repeatedly showed an increase from the 460BHP previously achieved, to 512BHP, creating gains of +52BHP. We repeated our testing to ensure our results were true and checked all our test vehicles sensor data to ensure there were no negative effects.

Finished in our specially formulated textured black finish, and supported by our lifetime guarantee, this is truly an outstanding performance-enhancing product.

Our History

For 23 years Speedzone Performance LLC has been providing aftermarket car parts to Central Floridians and 1000's of customers online. What makes us different than all the other places online? We have 3 actual brick and mortar locations where were serve customers daily and find new ways to provide support and assistance to the automotive community at large. From our in house SPDZ1 Brand, to our constantly growing in stock inventory, we strive to make our customer service and ease of purchase stand out from the rest! We are also one of the largest automotive part financing providers anywhere in the United States, and continue to provide more options for our customers every year. We love what we do, and it shows in every product we sell and every new customer who becomes a part of our Speedzone Family.